Untreated aluminium in historical buildings

At some point in time, aluminium was worth the price of gold. In some historical constructions, including the San Gioacchino Church in Rome, the Washington Monument, and the Eros Statue in London, the engineers have applied untreated aluminium, which, after more than 100 years, still has a beautiful and aesthetic look today.

High Corrosion Resistance despite Wind and Weather

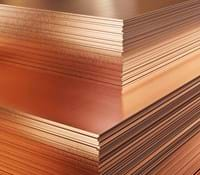

The San Gioacchino Church is not only known for its beautiful architecture and long-standing history as a Catholic monument: The impressive octagonal dome of the church is, among other things, coated with untreated aluminium sheets, which, for more than 100 years, have decorated the top of the church. The dome of the San Gioacchino is one of the oldest outdoor applications of aluminium known. Although these 18th-century aluminium sheets have been exposed to the hot Italian summers as well as to the cool winters with night temperatures down to 5° C, the untreated aluminium remains in a good condition.

The aluminium sheets applied to the dome were 1.3 cm thick, when they were put on in 1897. Examinations 50 years after the construction revealed that the corrosion depth was less than 0.1 mm. San Gioacchino’s dome is thus a perfect example of the high corrosion resistance of aluminium, even if the aluminium has received no kinds of anodising or surface treatment.

Increased Aluminium Content Increases the Corrosion Resistance

The alloy applied to the dome consists of 98% aluminium. Should you want to apply an untreated aluminium in similar constructions today, you would probably use a 99.5% pure aluminium (EN-AW 1050A) or magnesium-added alloys (EN-AW 5005 and EN-AW 5754).

Today’s purer aluminium as well as the addition of Magnesium provide a higher corrosion resistance – even if the material is exposed to changing weather conditions.

The Washington Monument and the Eros Statue in London

Rome is not the only place to find outdoor constructions with untreated aluminium in continuing excellent condition. The Washington Monument rises 169 meters in the air, and, on the top, a mere 22.6 cm high pyramidal top in untreated aluminium sits enthroned.

The monument was completed in 1884, and the original idea behind the aluminium part was that it should act as a lightning conductor, primarily. However, it should also have a colour matching the remaining parts of the stone monument.

The pyramid has a text engraved, and, upon inspection 50 years after the construction, the text was still readable. Examinations of the aluminium show that the alloy contains approximately 97% aluminium.

On Piccadilly Circus, in the heart of London, you will find the famous statue of the Greek god of love Eros. The statue was built in 1893 and is made of untreated aluminium. At that time, and for many years after, the atmosphere of Inner London was heavily contaminated. Upon a complete cleaning of the statue in 1953, it was found that the aluminium surface was still in perfect condition, and that there were no signs of corrosion despite the fact that the statue had been exposed to highly contaminated air for 60 years.

Learn more about the Eros Statue.

Learn more about the Eros Statue.

These three outdoor constructions made from untreated aluminium are all examples of the magnitude of the aluminium’s strong corrosion resistance and overall durability. Although all of the constructions were built back in the 1800s, they are still standing to this day and are expected to continue to do so for many more years.

Sources:

Binczewsk, G. (1995). The Point of a Monument: A History of the Aluminum Cap of the Washington Monument. I: JOM, 47 (11) (1995), pp. 20-25.

Tiscali. (2016). Found on: : http://myweb.tiscali.co.uk/speel/london/eros.htm (15. 06. 2016)

Vargel, C. (2004). Corrosion of aluminium. Elsevier.